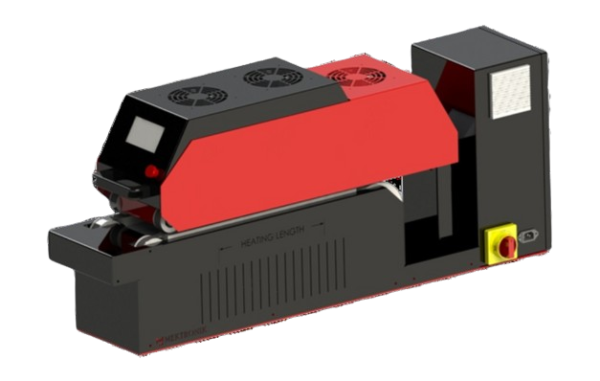

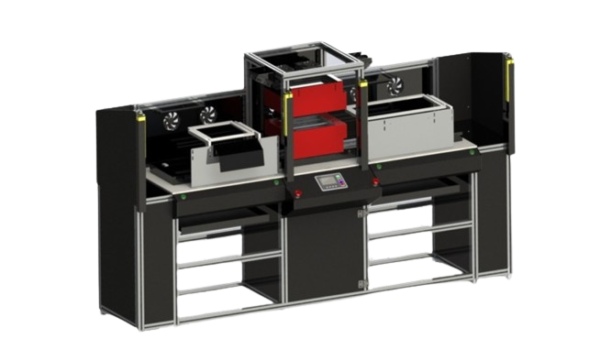

IR EcoShrink

The IR Eco, designed for various heat shrinking applications, serves as an excellent choice in the realm of infrared shrinking appliances. This BenchTop device was purpose-built as a stationary appliance for utilization on workstations.

| Weight: | 100 kg |

Product Description

Bid farewell to the burdensome labor expenses, excessive heat, and inefficacy. The Mektronik Eco shrink machine drastically reduces the time required for shrinking various heat shrink tubing types, while simultaneously enhancing process control and the overall quality of your shrinking operations.

What InfraRed Shrinking?

Hot air guns heat air through coils, which demand high power and have long warm-up times. In contrast, infrared technology uses electromagnetic radiation for faster, more efficient, and higher-quality heat shrinking.

Cost Saving

Better Processing time/Cycle time is important for every industry to achieve maximum production output. IR heating will improve significant cycle time compared to the traditional methods.

Uniform Heating.

Electric radiant heaters offer precise control and can be zoned for even 360-degree heat distribution on heat shrink tubes. Unlike hot air guns, they eliminate the need to rotate the cable, allowing for efficient cable shrinking. IR heating is more energy-efficient, with over 10 times the energy savings for heat shrinking tubes. This results in significantly faster shrink times and superior quality outcomes.

Energy Saving

IR technology uses 4-5 times less power than hot air guns, cutting operating costs. Unlike hot air guns, it has no warm-up time, thanks to instant heating technology, saving energy and resources during the shrinking process.

Quality

Uniform heating guarantees quality across all edges of heat shrink tubes, and precise control over time and intensity enhances the overall quality of your shrinking operation.

Specification

| Shrinking zone | 150X50 mm |

| Emitters | 2 Nos |

| Voltage | 230V AC |

| Emitter lifespan (estimate) | 5000(approx) hrs |